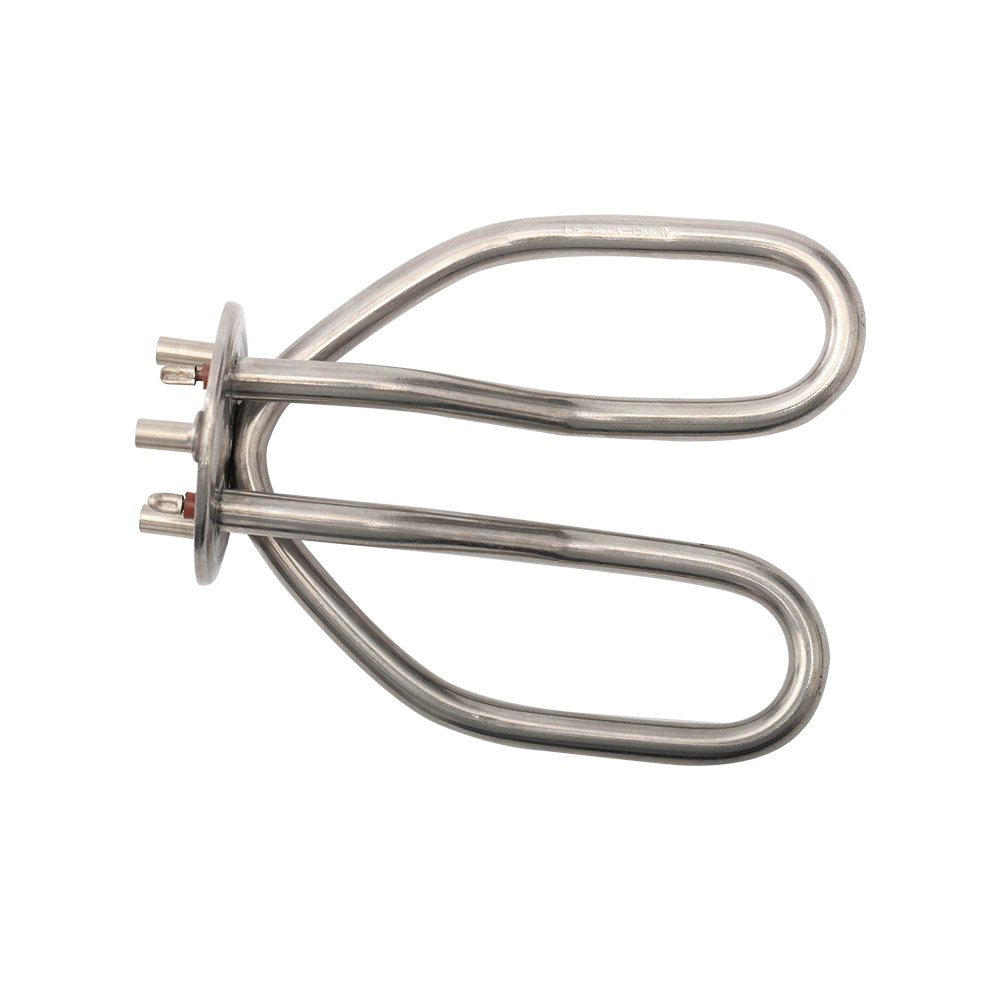

Kettle Heating Element

The kettle heating element is the key component in an electric kettle that provides heat. All kettle elements on the market work on a similar principle, when an electric current is passed through the heating element, the heating element generates a large amount of heat, causing the liquid inside the kettle to boil. Joulemax manufactures kettle heating elements made of 304 stainless steel material and high-performance magnesium oxide raw material.

If you want to purchase electric kettle heating elements in bulk. Browse various versions of kettle heating element on Joulemax to get wholesale deals. We have a huge range of kettle heating elements to suit you and your customers.

How to choose the right kettle heating element for your kettle? Depending on the size and capacity of the kettle, a higher wattage element will heat the liquid faster. Typically kettle heating elements made by Joulemax are usually rated between 1000 and 3000 watts.

How Much Does Kettle Heating Element Cost?

We offer a full solution for Kettle Heating Elements: One ring, Two ring, Three ring, different types of power, different pipes, different magnesium powder and all kinds of resistance wires.

The Kettle Heating Element price and cost depend on what technology you select, manufacturer ability, quantity, the price of raw materials and we also accept customize your own design and brand. To order the best kettle heating element suitable for your business, please contact us for more details.

We can offer the OEM/ODM services of our products. The product can be customized according to your personalized requirements, including the brand, label, painting colors, shape and power of electric heating element, and packing box. Please offer your design documents or tell us your ideas and our R&D team will do the rest.

Frequently Asked Questions

Why Choose Us

Our sales and engineering services are available at your convenience, whenever you need us. Whether it’s 11:00 pm on a Saturday night, or 7:00 am on Monday morning, it makes no difference to us. We’re always available to assist you with your order or answer any questions you may have about our manufacturing services.

Prefer to call us? Talk to a Joulemax Expert at +86-181-5820-2116

Manufacturing Technique

Certifications

China Heating Elements Supplier and Factory

Joulemax focuses on the design, development, and manufacture of electric heating elements, thermostats as well as other related products. Our products have obtained CE and RoHS certification and the company has been ISO9001 certified.

Joulemax uses its own testing laboratory and a number of advanced testing equipment to conduct product testing to make sure of the high quality and pass rate of products. Under the strict management system, accurate delivery time is assured every time.

We strictly select our suppliers and strictly control the quality of each raw material and accessories including magnesium oxide, resistors, pipes and so on.